Difference between revisions of "Manufacturing Process"

(Created page with "The Xbox was manufactured in three countries throughout its lifetime: Guadalajara, Mexico; Sárvár, Hungary; and Doumen, China. == Serial Number == File:Serial-sticker.jp...") |

KaosEngineer (talk | contribs) m (Fixed link to show more than [1] but the article title.) |

||

| (6 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | The Xbox was manufactured in | + | [[File:Manufacturing26.jpg|thumb|Sárvár, Hungary factory]] |

| + | |||

| + | The Xbox was manufactured by Flextronics in four locations throughout its lifetime: Guadalajara, Mexico; Sárvár, Hungary; Doumen, China; and Taiwan{{FIXME|reason=City?}}. | ||

== Serial Number == | == Serial Number == | ||

| Line 15: | Line 17: | ||

|} | |} | ||

| − | The first field is the factory production line number. The second field is the Xbox's number for the week (for the whole factory, not just the one line). The third field is the last digit of the year. The fourth field is the week of the year. Finally, the fifth field is the factory number. Mexico is 02, Hungary is 03, | + | The first field is the factory production line number. The second field is the Xbox's number for the week (for the whole factory, not just the one line). The third field is the last digit of the year. The fourth field is the week of the year. Finally, the fifth field is the factory number. Mexico is 02, Hungary is 03, China is 05, and Taiwan is 06. |

So this Xbox was the 166,356<sup>th</sup> to be manufactured in week 9 of the year 2002 on production line 1 in Sárvár, Hungary. | So this Xbox was the 166,356<sup>th</sup> to be manufactured in week 9 of the year 2002 on production line 1 in Sárvár, Hungary. | ||

| + | |||

| + | The bar code is the 12-digit serial number in standard [https://en.wikipedia.org/wiki/Code_39 Code 39] format. | ||

== Timeline == | == Timeline == | ||

| Line 115: | Line 119: | ||

The overall process didn't vary much between hardware revisions. The only notable change was related to the BIOS ROM. Up until version 1.6, the BIOS was flashed onto a TSOP ROM before being soldered to the motherboard. Revision 1.6 introduced the Xyclops chip, which integrated both the [[System Management Controller]] and the BIOS ROM on a single die. This meant the BIOS had to be flashed by the chip manufacturer instead of on the Xbox production line. | The overall process didn't vary much between hardware revisions. The only notable change was related to the BIOS ROM. Up until version 1.6, the BIOS was flashed onto a TSOP ROM before being soldered to the motherboard. Revision 1.6 introduced the Xyclops chip, which integrated both the [[System Management Controller]] and the BIOS ROM on a single die. This meant the BIOS had to be flashed by the chip manufacturer instead of on the Xbox production line. | ||

| + | |||

| + | <gallery> | ||

| + | File:Manufacturing19.jpg|Plastic case molding & assembly. | ||

| + | File:Manufacturing18.jpg|Lids | ||

| + | File:Manufacturing9.jpg|Green jewels | ||

| + | File:Manufacturing10.jpg|Green jewels | ||

| + | File:Manufacturing16.jpg|Jewels are dispensed from hoppers. | ||

| + | File:Manufacturing7.jpg|Lid shield is positioned. | ||

| + | File:Manufacturing3.jpg|Lid is placed over shield. | ||

| + | File:Manufacturing5.jpg|Jewel is aligned... | ||

| + | File:Manufacturing4.jpg|...and then applied. | ||

| + | File:Manufacturing6.jpg|The tape is left on to prevent scratches. | ||

| + | File:Manufacturing15.jpg|Shield and drive caddies are installed in the bottom half. | ||

| + | File:Manufacturing20.jpg|Assembled cases are placed on pallets. | ||

| + | File:Manufacturing11.jpg | ||

| + | File:Manufacturing12.jpg | ||

| + | File:Manufacturing13.jpg | ||

| + | File:Manufacturing14.jpg|Cases ready for their electronics. | ||

| + | File:Manufacturing25.jpg|Components arrive in bulk at the assembly line. | ||

| + | File:Manufacturing26.jpg | ||

| + | File:Manufacturing24.jpg|Technicians assemble components. | ||

| + | File:Manufacturing23.jpg | ||

| + | File:Manufacturing22.jpg | ||

| + | File:Manufacturing27.jpg | ||

| + | File:Manufacturing28.jpg | ||

| + | File:Manufacturing21.jpg|Fully assembled consoles are placed on carts, ready for initialization. | ||

| + | </gallery> | ||

== Software initialization == | == Software initialization == | ||

| Line 145: | Line 176: | ||

Xbox kernels since version 4034 have another backdoor that even works if the EEPROM check succeeds: If bit 30 of the media flag of an XBE is set, the condition of the hard disk is ignored as well. This change allows Microsoft to replace broken hard disks without replacing a valid EEPROM on an Xbox sent in for repair. Before this change, they had to rewrite the EEPROM whenever they replaced the drive. | Xbox kernels since version 4034 have another backdoor that even works if the EEPROM check succeeds: If bit 30 of the media flag of an XBE is set, the condition of the hard disk is ignored as well. This change allows Microsoft to replace broken hard disks without replacing a valid EEPROM on an Xbox sent in for repair. Before this change, they had to rewrite the EEPROM whenever they replaced the drive. | ||

| + | |||

| + | <gallery> | ||

| + | File:Manufacturing30.jpg|Consoles are initialized by setup program. | ||

| + | File:Manufacturing33.jpg|Initialized consoles undergo final integration testing. | ||

| + | File:Manufacturing34.jpg | ||

| + | File:Manufacturing2.jpg | ||

| + | </gallery> | ||

| + | |||

| + | == Packing and shipping == | ||

| + | |||

| + | <gallery> | ||

| + | File:Manufacturing17.jpg|Styrofoam inserts are prepared. | ||

| + | File:Manufacturing31.jpg|Consoles are packed into boxes. | ||

| + | File:Manufacturing32.jpg|Boxes are sealed... | ||

| + | File:Manufacturing29.jpg|...and loaded on pallets, ready for shipping. | ||

| + | </gallery> | ||

| + | |||

| + | == Videos == | ||

| + | |||

| + | * [https://www.youtube.com/watch?v=iWQb7LGH71s Xbox Factory Tour Video (Sárvár, Hungary; 2002)] - Demonstrates almost the entire assembly process from start to finish (not including case manufacturing). | ||

| + | * [https://www.youtube.com/watch?v=_iR0eNuyUKI Flextronics Advertisement] - Contains still photos of the PCB manufacturing and testing processes. | ||

| + | |||

| + | == Further Reading == | ||

| + | |||

| + | * [https://web.archive.org/web/20100617013616/http://www.ifm.eng.cam.ac.uk/ctm/idm/cases/xbox.html Case study - Microsoft Xbox], Innovation and Design Management, University of Cambridge | ||

| + | * O'Brien, J. [https://web.archive.org/web/20100617013616/http://www.wired.com/wired/archive/9.11/flex_pr.html The making of the Xbox], Wired, Issue 9.11, November 2001 | ||

| + | * Shah, J. and Serant, C. [https://web.archive.org/web/20100617013616/http://www.ebnonline.com/story/OEG20020311S0076 Microsoft's Xbox sets supply chain standard], EBN Online, 11 March 2002 | ||

| + | * Olavsrud, T. [https://web.archive.org/web/20100617013616/http://www.internetnews.com/bus-news/article.php/1129171 Flextronics relocates Xbox manufacturing facility], Internetnews.com, 15 May 2002 | ||

| + | * Penz, B. [https://web.archive.org/web/20100617013616/http://www.amcham.hu/BusinessHungary/16-06/articles/16-06_27.asp Game Over? Xbox production heads east], Business Hungary, Vol 16 No 6, June 2002 | ||

| + | * Carbone, J. [https://web.archive.org/web/20100617013616/http://manufacturing.net/pur/article/CA237778?stt=001&pubdate=08%2F15%2F02 Outsourcing the Xbox], Purchasing Magazine Online, 15 August 2002 | ||

| + | * Neilley, R. [https://www.plasticstoday.com/molding-big-man-campus Molding is big man on this campus], PlasticsToday, 1 December 2001 | ||

== Credits == | == Credits == | ||

This article is adapted from [https://web.archive.org/web/20100617013616/http://www.xbox-linux.org/wiki/Xbox_Manufacturing_Process Xbox Manufacturing Process] by Michael Steil. Its content is reproduced here under the [https://www.gnu.org/licenses/old-licenses/fdl-1.2.en.html GNU Free Documentation License 1.2]. | This article is adapted from [https://web.archive.org/web/20100617013616/http://www.xbox-linux.org/wiki/Xbox_Manufacturing_Process Xbox Manufacturing Process] by Michael Steil. Its content is reproduced here under the [https://www.gnu.org/licenses/old-licenses/fdl-1.2.en.html GNU Free Documentation License 1.2]. | ||

| + | |||

| + | Production line photos are from [https://web.archive.org/web/20100608022830/http://andy.saturn9.ws:80/Photo%20Albums/Xbox%20Manufacturing%20Facility/ Andy Rostad's gallery]. | ||

Latest revision as of 02:13, 23 October 2021

The Xbox was manufactured by Flextronics in four locations throughout its lifetime: Guadalajara, Mexico; Sárvár, Hungary; Doumen, China; and Taiwan[FIXME].

Contents

Serial Number

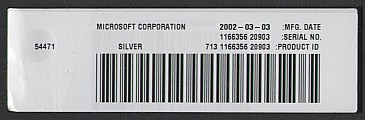

Every Xbox has a sticker on the bottom with a manufacturing date and a 12-digit serial number. The serial number encodes information about where and when the hardware was manufactured.

Using the pictured serial number as an example:

| Line | Number | Year | Week | Factory |

|---|---|---|---|---|

| 1 | 166356 | 2 | 09 | 03 |

The first field is the factory production line number. The second field is the Xbox's number for the week (for the whole factory, not just the one line). The third field is the last digit of the year. The fourth field is the week of the year. Finally, the fifth field is the factory number. Mexico is 02, Hungary is 03, China is 05, and Taiwan is 06.

So this Xbox was the 166,356th to be manufactured in week 9 of the year 2002 on production line 1 in Sárvár, Hungary.

The bar code is the 12-digit serial number in standard Code 39 format.

Timeline

| Mexico | Hungary | China | |

|---|---|---|---|

| 2001 | |||

| October | Production of 110V 1.0 Xboxes with Thomson DVD drives begins for USA/Canada. | ||

| 2002 | |||

| January | Production begins for Japan. | Production switches to 220V 1.0 models for Europe/Australia. | |

| April | Production lines 1 and 6 are moved to China. 50% of new units now produced with Philips DVD drives. | [FIXME] | |

| May | Production stops after ~3 million units. All four production lines moved to China. | ||

| August | Production of the 220V 1.1 Xbox for Europe/Australia begins, with mostly Philips and sometimes Thomson DVD drives. | ||

| September | Most units now use Samsung DVD drives. | ||

| October | Remaining four lines switched to version 1.1. | ||

| November | Production extended to 110V USA/Canada/Japan models. | ||

| December | Production ends after ~7 million units. | First line changes to version 1.2. | |

| 2003 | |||

| February | Last line changes to version 1.2. | ||

| March | First line changes to version 1.3. | ||

| April | Last line changes to version 1.3. | ||

| July | First line changes to version 1.4. | ||

| August | First line changes to version 1.5. | ||

| 2004 [FIXME] | |||

| ? | ? | ||

Hardware assembly

The Xbox was manufactured just like many other mass-produced electronic products. Printed circuit boards were made in bulk and populated by pick-and-place machines, the plastic case was formed by injection molding, and finally all of the pieces were assembled by hand on production lines.

The overall process didn't vary much between hardware revisions. The only notable change was related to the BIOS ROM. Up until version 1.6, the BIOS was flashed onto a TSOP ROM before being soldered to the motherboard. Revision 1.6 introduced the Xyclops chip, which integrated both the System Management Controller and the BIOS ROM on a single die. This meant the BIOS had to be flashed by the chip manufacturer instead of on the Xbox production line.

Software initialization

When a fully-assembled Xbox reached the end of the production line, it had a:

- valid BIOS image

- blank EEPROM

- blank, unlocked hard disk

To initialize the EEPROM and hard disk in the final stage of production, a technician would insert a DVD containing a setup program. The setup program, named default.xbe just like any other primary Xbox executable, was built by the XDK with the "allow eject" flag set and the region code set to 0x80000000 ("DEBUG").

When the Xbox kernel initializes, it checksums the EEPROM. If it fails, the Xbox will be in DEBUG mode, i.e. the region code is set to 0x80000000. With the region code set to this value, the kernel ignores it if the hard disk is not locked. Because the region code matches, the kernel will run the executable from the DVD, which does the following:

- Format the three swap partitions

- Copy XMTAXBOX.XBE from the DVD to the first cache partition and run it

Then the DVD can be ejected and put into the next Xbox.

XMTAXBOX.XBE

This XMTAXBOX.XBE is an XBE retail-signed for hard disk, also with the region code set to 0x80000000, that does the following:

- Retrieve the EEPROM contents from a network server

- Retrieve the contents of the system and data partitions from a network server

- Lock the hard disk

- Run some self tests and send a report to the server

A new Xbox still contains the file XMTAXBOX.XBE on the first cache partition, as well as some temporary files on the third one.

Xbox kernels since version 4034 have another backdoor that even works if the EEPROM check succeeds: If bit 30 of the media flag of an XBE is set, the condition of the hard disk is ignored as well. This change allows Microsoft to replace broken hard disks without replacing a valid EEPROM on an Xbox sent in for repair. Before this change, they had to rewrite the EEPROM whenever they replaced the drive.

Packing and shipping

Videos

- Xbox Factory Tour Video (Sárvár, Hungary; 2002) - Demonstrates almost the entire assembly process from start to finish (not including case manufacturing).

- Flextronics Advertisement - Contains still photos of the PCB manufacturing and testing processes.

Further Reading

- Case study - Microsoft Xbox, Innovation and Design Management, University of Cambridge

- O'Brien, J. The making of the Xbox, Wired, Issue 9.11, November 2001

- Shah, J. and Serant, C. Microsoft's Xbox sets supply chain standard, EBN Online, 11 March 2002

- Olavsrud, T. Flextronics relocates Xbox manufacturing facility, Internetnews.com, 15 May 2002

- Penz, B. Game Over? Xbox production heads east, Business Hungary, Vol 16 No 6, June 2002

- Carbone, J. Outsourcing the Xbox, Purchasing Magazine Online, 15 August 2002

- Neilley, R. Molding is big man on this campus, PlasticsToday, 1 December 2001

Credits

This article is adapted from Xbox Manufacturing Process by Michael Steil. Its content is reproduced here under the GNU Free Documentation License 1.2.

Production line photos are from Andy Rostad's gallery.